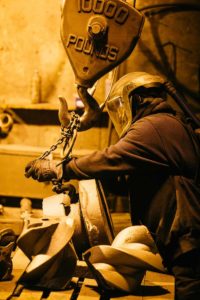

The Taylor & Fenn Company has been sand casting parts and equipment for the building and construction industry for decades. One of our most established clients is an OEM specializing in the design and production of elevators for large buildings, industrial facilities, and residences.

Producing Components in A Variety of Sizes

Producing Components in A Variety of Sizes

Over the years, we have produced a variety of elevator components for this OEM; from smaller pieces—such as sprockets and shivs—to large power generation units such as turbine housings and more. Recently, the customer requested a series of drive pulleys in various sizes.

Our spacious shop floor gives us the ability to produce components in a range of sizes, including large floor molds for parts as large as 6,000 lbs. This gives our team the flexibility to accommodate orders for clients who need multiple pieces in a series of sizes. Because this was a familiar customer, we were able to use the existing patterns from previous orders we’ve fulfilled for them in the past. However, our team has the capability to provide custom patterns or design feedback if required.

Material Considerations and Custom Alloys

Material choice is an important part of the sand casting process, as it can affect the longevity and performance of the finished product. This client typically specifies custom alloys which they provide. The Taylor & Fenn Company has the capability to work with more than 100 different grades of iron and steel. Our expert team also includes trained metallurgists who are able to provide feedback and support if the material choice is still being considered.

OEMs in the building and construction industry trust the Taylor & Fenn company to provide reliable, quality components. For more information about sand casting building and construction equipment, contact us today.